Revolutionizing Diffraction Gratings

optics for the next generation of

Augmented Reality (AR) smart glasses and

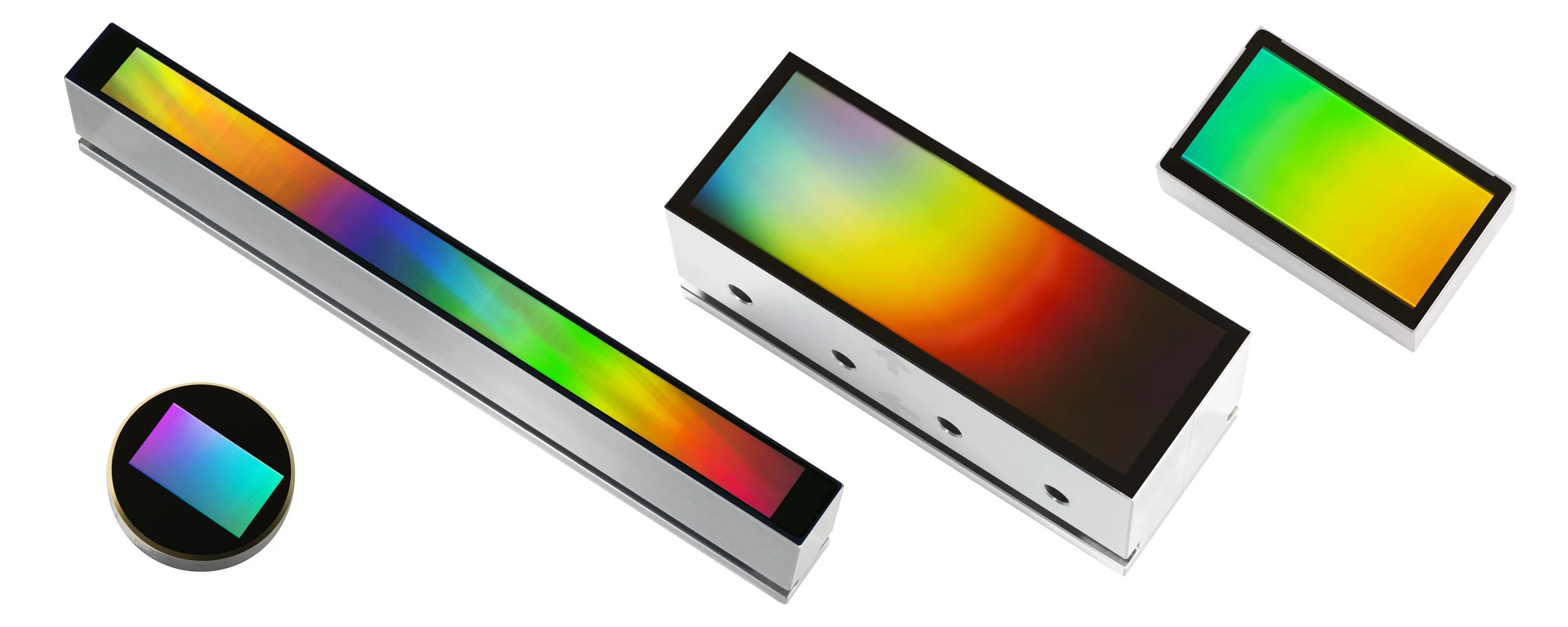

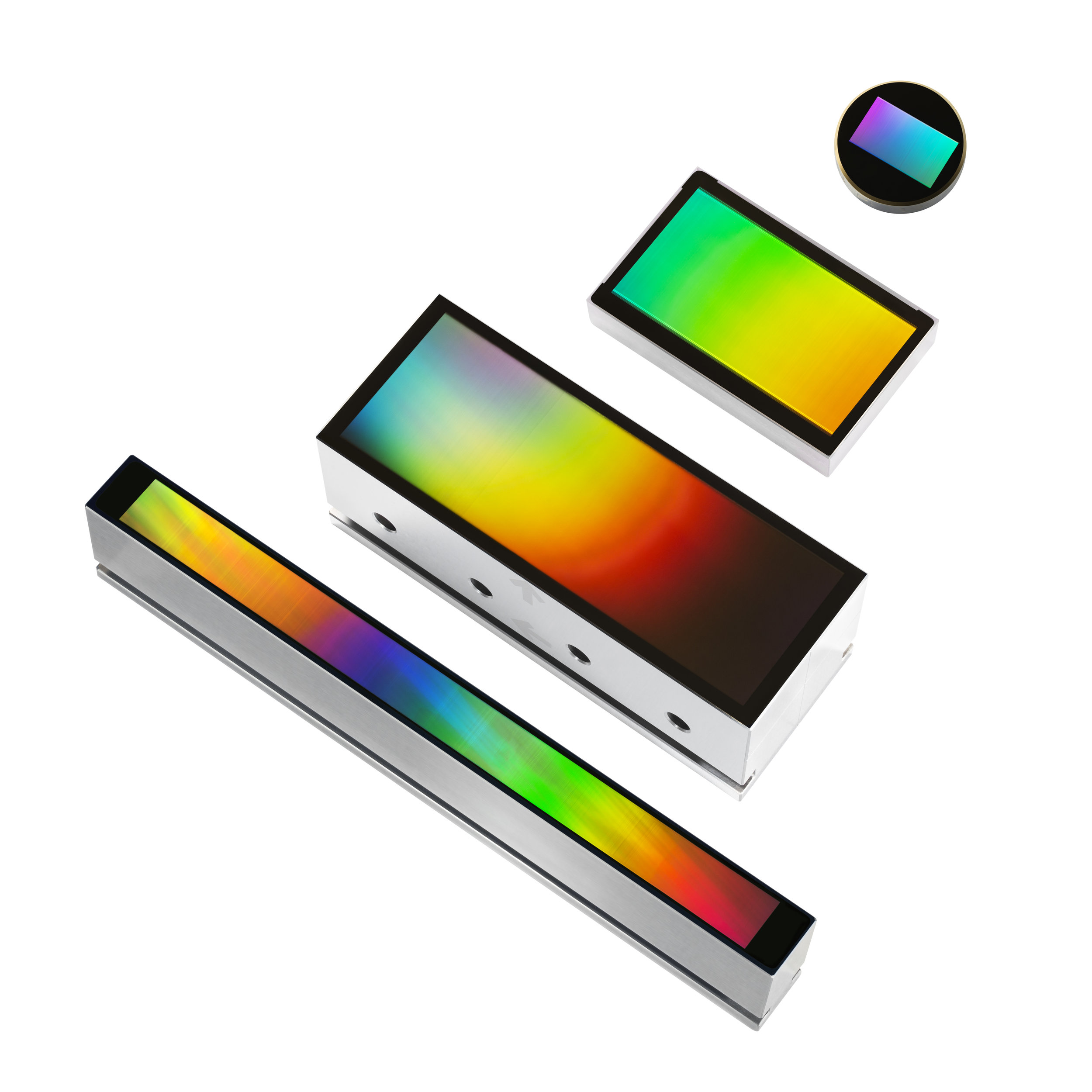

BLAZED MASTER GRATINGS FOR INDUSTRY and research

• AR Grating Master Molds • Blazed Grating Waveguide Solutions • High Efficiency • No write-field limitations

• AR Grating Master Molds • Blazed Grating Waveguide Solutions • High Efficiency • No write-field limitations

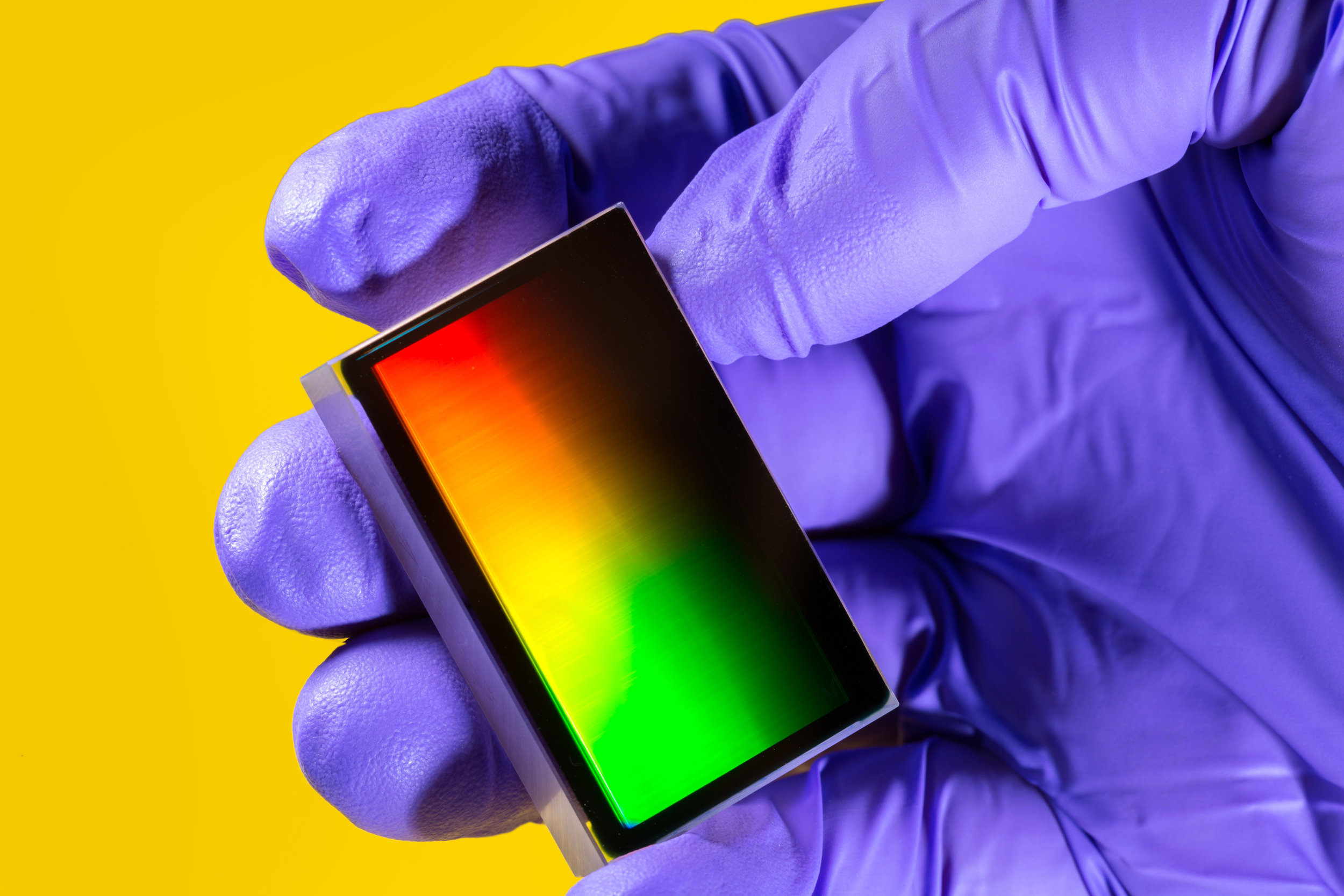

Inprentus-created AR Waveguide (1.9 index) replicated in collaboration with Inkron

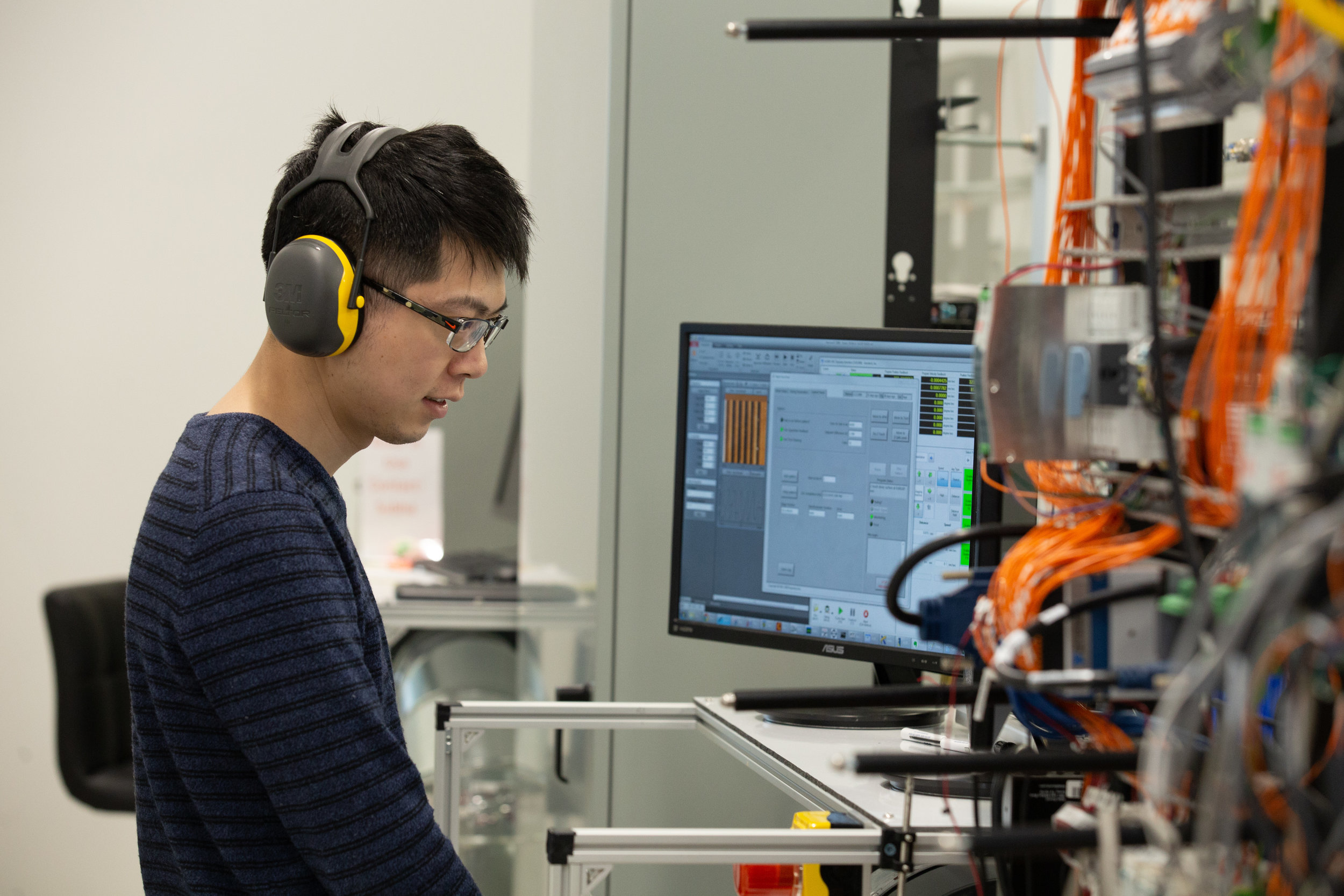

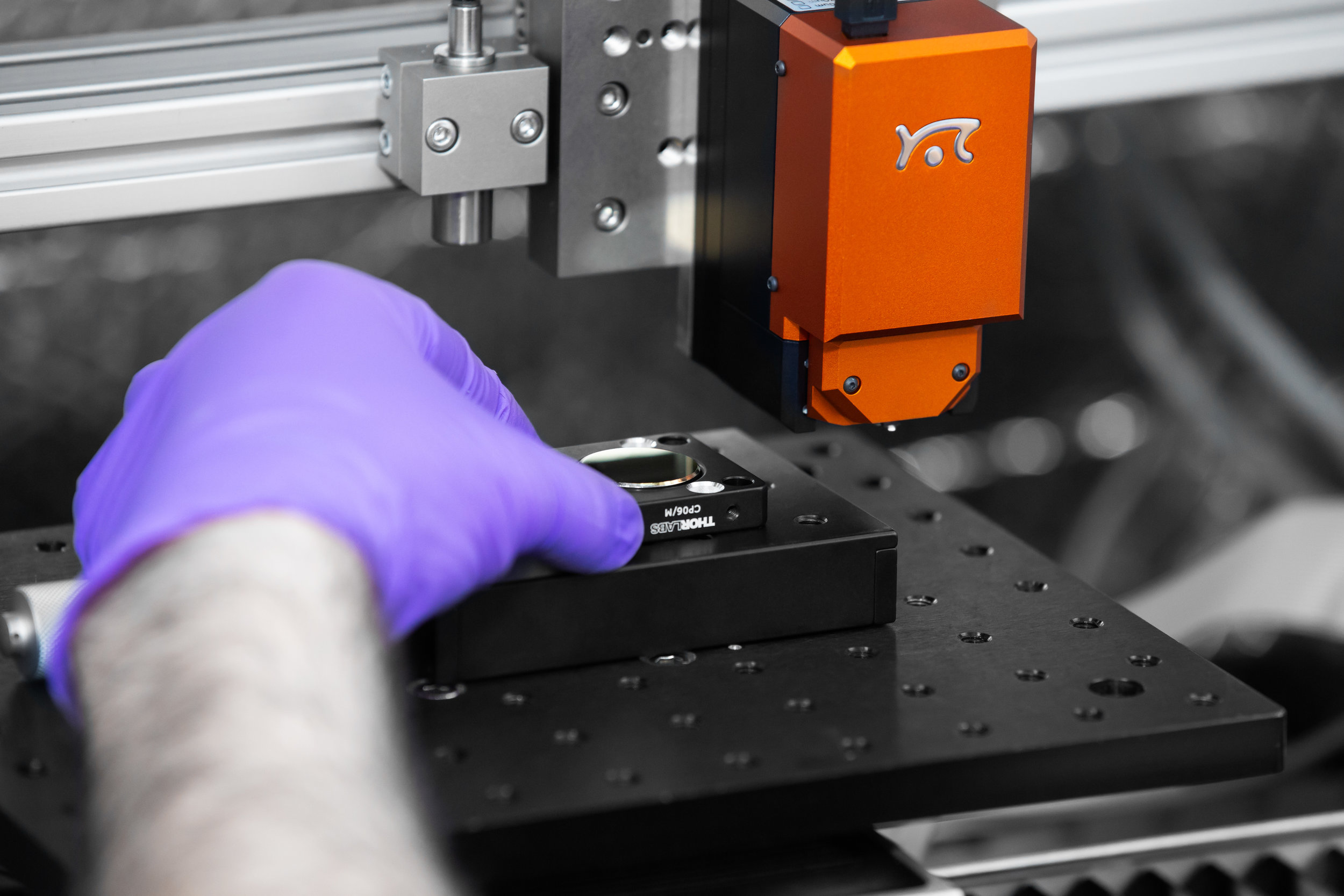

Inprentus has 10+ years of experience in designing, optimizing, and manufacturing the world’s most complex blazed master diffraction gratings. Our gratings are used in a variety of applications, including synchrotron and free electron lasers, OEM system optimization, EUV, and Augmented Reality (AR). Inprentus leads the world in a unique nano-scale lithography manufacturing technique known as mechanical ruling. With our revolutionary technique, Inprentus can create modulated gratings with curved lines or varying depth.

““Inprentus gratings have been key to enabling our company to create an entirely new product offering””

Start a project with us

Learn More ...

About Diffraction Gratings

A diffraction grating is a periodic structure patterned into a reflective surface, which disperses light into its constituent wavelengths.

Gratings separate light into its "colors”, similar to a prism.

Allows for the control and manipulation of light.

Used in all applications in which the wavelength of light must be tuned (spectroscopy, imaging, etc.), including semiconductor manufacturing, augmented reality (AR), and in materials, chemistry, and life sciences research.

About Our Gratings

Custom Blazed Diffraction Gratings manufactured by Inprentus are used with X-Ray, UV, and Visible Light applications. Our revolutionary manufacturing techniques allow for the creation of ultra high line density and high-precision patterning of surfaces. Our exacting manufacturing process, testing program, and packaging operations ensure the highest standard of quality, providing gratings that are thoroughly clean and free from any organic low vapor pressure material or organic fluid. Each diffraction grating is measured with a variety of optical metrology instruments, and test results are provided with the delivery of each diffraction grating.