Spectroscopy

Blazed Diffraction Grating Masters

Blazed Diffraction Gratings for Spectroscopy

Inprentus offers custom blazed diffraction grating masters for spectroscopy applications where optimization of optical efficiency is a priority.

A Modernized Method for Mechanical Ruling of Blazed Diffraction Gratings

Low manufacturing yield has traditionally limited the industry, causing long lead times for grating delivery. The Inprentus method has revolutionized the core manufacturing process for blazed diffraction grating production, providing the industry with a valuable new source for high-precision products. Improved specifications include optical bandwidth resolution and enhancements of optical efficiency.

Design to Delivery

Inprentus will work with you to design and calculate simulated specifications and assist you with your grating design. Inprentus blazed master diffraction gratings can be sold with replication rights for use in your company’s products.

Master Gratings for ICP-OES Applications

Inprentus can manufacture Echelle gratings specifically optimized for high blaze efficiency in a range of wavelengths in the UV to IR region and in a wide variety of sizes and specifications. The blazed master diffraction gratings are used as-is or can be replicated for cutting-edge spectroscopy applications. Inprentus works closely with customers to provide custom blaze angles in the grating masters to enable optimized end-replication efficiency.

Performance - High Grating Efficiency

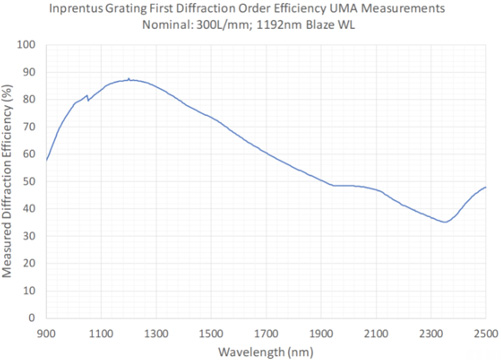

Inprentus 300 lpmm spectroscopy grating sample was verified to give more than 80% efficiency at design wavelength. The measurement was performed by a third party using an industry standard spectrophotometer.

Nano-manufacturing Precision Grooves

The 300 lpmm spectroscopy grating sample has been manufactured to have a blaze angle of 10.5° ± 0.2°. An atomic force microscope (AFM) grayscale height map of manufactured grooves is shown (left) along with groove profile in blue.