Semiconductor

Blazed Diffraction Gratings

EUV - Blazed Diffraction Gratings for OEMS

Inprentus offers custom master blazed diffraction gratings for EUV applications where optimization of optical efficiency, instrument compactness, and performance are priorities for next generation processing labs. Inprentus has the ability to manufacture blazed diffraction gratings with extreme focusing abilities using high variable line spacing (VLS). This leads to optimization towards reduced spot size and brighter light at the operating wavelength. The gratings can be used in and around design wavelengths in a wide variety of sizes and specifications, enabling compact instrument designs and upgrades. Inprentus also works closely with customers to provide custom blaze angles in the blazed diffraction grating masters to enable a drop-in replacement in a current instrument or next-generation instrument upgrade.

“Inprentus gratings have been key to enabling our company to create an entirely new product offering”

EUV Tech, Martinez, CA

Blazed Diffraction Grating Specifications

- Blaze angles from 0.1° to 80°

- VLS - Variable Line Spacing (VLS)

- Echelle gratings

- Ruling on curved substrates – concave, toroidal, elliptical

- Resolving power above 100,000 (dependent on other specifications)

- High damage threshold substrates and overcoatings available

- Dimensions up to 500 x 200mm

- Line densities from 50 to 3000 l/mm

- Gold (Au) coated ruling surface with silicon or fused silica substrates

Performance: High Grating Efficiency

Inprentus 824 lpmm custom EUV grating with extreme VLS was verified to provide near-ideal

efficiency at design wavelength. Compare to simulated efficiency in figure 4. The measurement

was performed at the Center for X-Ray Optics at Lawrence Berkeley National Laboratory.

Upgrades: Extreme Focusing

Focused image size can be reduced by around 50x and the instrument made smaller using high

VLS gratings. Efficiency measured at different points on a high VLS grating is shown. The

differences are consistent with designed high line density variation. Inprentus has experience with

manufacturing blazed diffraction gratings with line spacing variation of 100% and more.

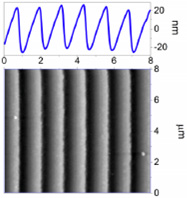

Nanomanufacturing: Precision Blaze Angle

Manufacturing advancements have enabled this EUV VLS grating to have line density extrema

ranging from 736 lpmm to 930 lpmm while maintaining a blaze angle of 3.3° +/- 0.04°. An

atomic force microscope (AFM) grayscale height map of manufactured grooves is shown below

along with groove profile in blue.

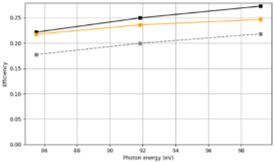

Support Capabilities: Efficiency Simulation

Proprietary simulation allows manufacturing setup to be precisely modified until the grating

yields efficiency (orange) above 80% (grey) of theoretical (black) efficiency. Simulated efficiency

is included in the FAT report and agrees with measured performance.