Synchrotron and FEL

Blazed Diffraction Gratings

Inprentus manufactures blazed diffraction gratings for x-ray and ultraviolet applications using a nano-scale, contact-mode lithography technique, a method of controlled mechanical deformation of metallic surfaces. This technology is particularly suited to x-ray and UV diffractive optics in which features must be shaped with 0.1-degree angular precision and positioned with nanometer precision over distances of tens of centimeters.⠀

High-Efficiency VLS Blazed Diffraction Gratings for Synchrotron and FEL Applications

- Simulation services for reliable predictions of in-beamline grating efficiency

- Diffraction gratings for beamline diagnostics

- Line densities at thousands of lines per millimeter

- Variable line spacing (VLS)

- Ultra-low Blaze angles - as low as 0.1 degree – for improved efficiency

- Large gratings up to 500 mm in length

- Broad range of optics design capabilities

VLS Blazed Diffraction Gratings for FEL Applications

High-efficiency mechanically ruled VLS blazed Diffraction Gratings

- Diffraction gratings for beamline diagnostics

- Ultra-low blaze angles for improved efficiency

- Simulation services for reliable predictions of in-beamline grating efficiency

Inprentus manufactures blazed diffraction gratings for x-ray and ultraviolet applications using a nano-scale, contact-mode lithography technique - a method of controlled mechanical deformation of metallic surfaces. This technology is particularly suited to x-ray and UV diffractive optics in which features must be shaped with 0.1-degree angular precision and positioned with nanometer precision over distances of tens of centimeters.

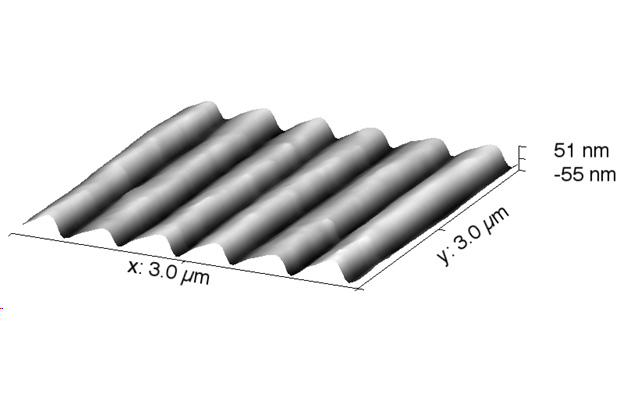

Blaze Angle Profiles

Ultra low blaze angles improve efficiency and can be manufactured by Inprentus. A single unsmoothed AFM trace of a 50 lines/mm grating with a blaze angle of 0.1°

Diagnostic Gratings

Diagnostic gratings can be custom designed to meet the needs of any FEL application. Using the spectral reflection of the coated grating and zeroith order diffraction of the grating, the majority of photons may be passed downstream to the beamlines, with a small fraction being directed into a spectrometer for in-situ diagnostics of each pulse train generated by the laser.

Blaze Angle Profiles

Ultra low blaze angles improve efficiency and can be manufactured by Inprentus. A single unsmoothed AFM trace of a 50 lines/mm grating with a blaze angle of 0.1°

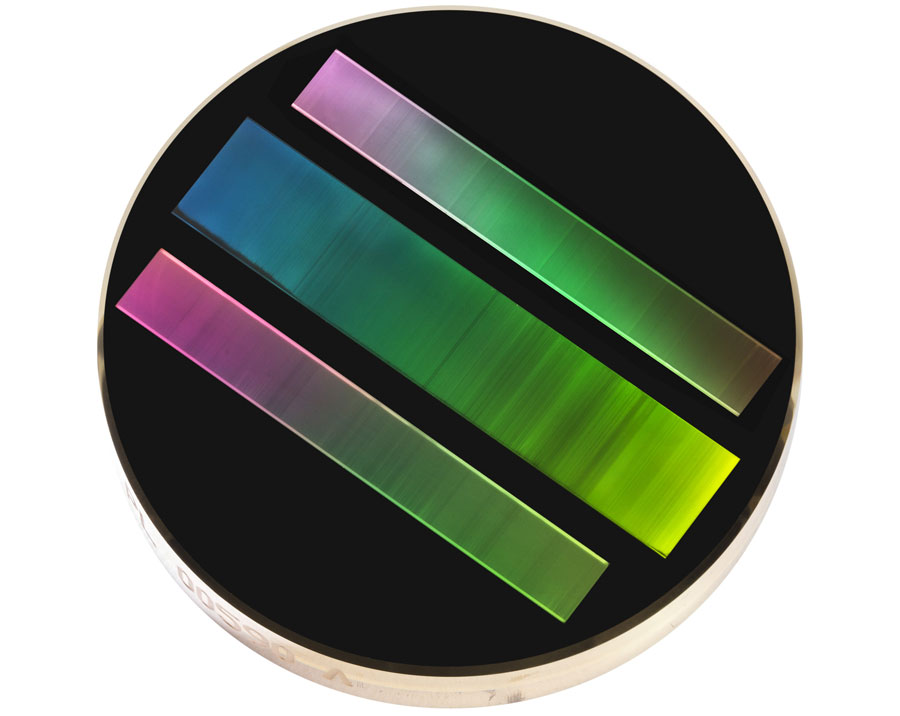

Blaze Facets

Inprentus can create blaze angles below 1.0° with line densities from 50 to over 5000 lines per milimeter.

Simulations

Inprentus simulation services are available with all grating purchases and provide reliable predictions of in-beamline grating efficiency.

RIXS

Resonant Inelastic X-ray Scattering (RIXS) data from Beamline 8.0.1 at the Advanced Light Source at Lawrence Berkeley National Laboratory.